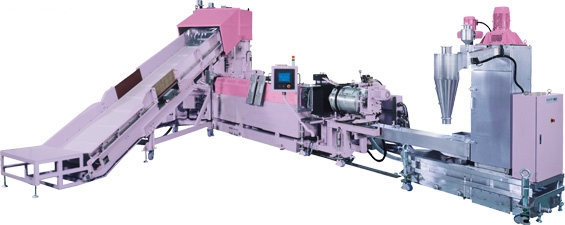

Plastic Related Equipment

Plastic Recycling Machine

Model:HuSS series

| Recycling plastic for | PP,PE,PS,ABS,PC,PA,PET....etc | Throughput | 100kg/h - 1,000kg/h |

|---|

I. Compactor type

- Main Use

- Crushed and Washed plastic, Plastic film

- Main Features

- High speed crusher gives the friction heating before extruder.

- It can be reduced the moisture, water contents.

II. Tandem type

- Main Use

- High contamination material, Post consumer material

- Main Features

- 2 extrusions make good de-gassing and good filtration with 2 screen changers.

III. One shaft type

- Main Use

- Inline recycling especially for edge trim. Block plastics, Lamps

- Main Features

- One shaft shredder makes plastics small pieces.

- It makes good constant output and good quality pellets.

IV. Force feeding type

- Main Use

- EPS,XPS ...expanded plastic material

- Main Features

- The force feeding device which is integrated on extruder can give high throughput even very light materials.

Video

| Model | Extruder | Capacity | |||

|---|---|---|---|---|---|

| Feeding part | Diameter(mm) | L/D | Vent | (kg/h) | |

| HuSS105V | Conical | φ105 | 37 | Yes | 300-400 |

| HuSS105VI | Straight | φ105 | 37 | Yes | 300-500 |

| HuSS85V | Conical | φ85 | 34 | Yes | 200-300 |

| HuSS85VI | Straight | φ85 | 34 | Yes | 200-400 |

| HuSS105 | Conical | φ105 | 23 | None | 300-400 |

| HuSS105I | Straight | φ105 | 23 | None | 300-500 |

| HuSS85 | Conical | φ85 | 22 | None | 200-300 |

| HuSS85I | Straight | φ85 | 22 | None | 200-400 |

*Specifications can be customized according to your requirements.

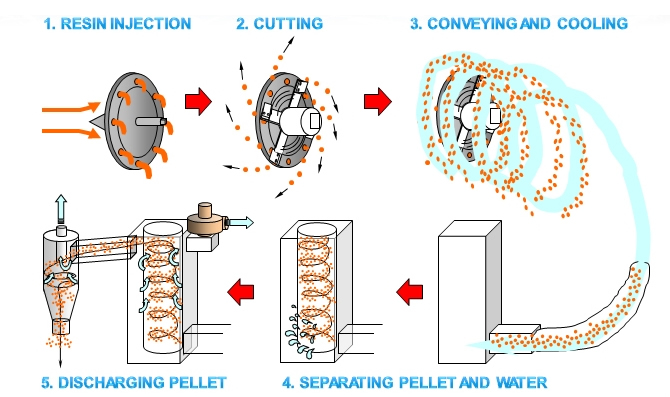

Water ring type Hot cut pelletizer

Model:G*** series

- Main Use

- Pelletizing PP, HDPE, LDPE, LLDPE, ABS, PS…etc

- Main Features

- Easy start-up and user friendly operation.

- Stable and high-quality pelletizing.

- Compact space saving design.

Operating Principles of Pelletizer

Model | G100 | G300 | G500 | G1000 |

|---|---|---|---|---|

Capacity(kg/h) | 150 | 350 | 700 | 1500 |

*Specifications can be customized according to your requirements.